AMPREG 31 Epoxy Resin/Hardener 1.26kg/4.66kg Pack

$77.00 – $297.00 incl. GST

- Same 100:26 resin to hardener mix ratio by weight across range of hardener speeds

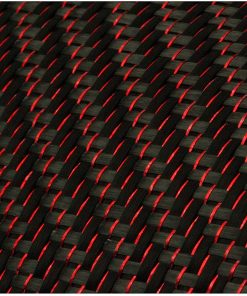

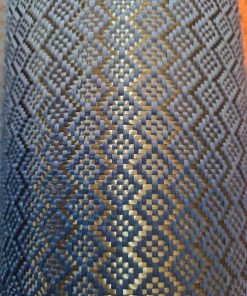

- Viscosity optimised for good fabric wet-out and drainage resistance

- Good cure progression from ambient only cures

- Tough resin matrix giving good laminate mechanical properties

Description

Ampreg™ 31 has been optimised for the manufacture of large composite structures using hand layup and vacuum bagging techniques whilst offering improved health and safety.

- Same 100:26 resin to hardener mix ratio by weight across range of hardener speeds

- Viscosity optimised for good fabric wet-out and drainage resistance

- Good cure progression from ambient only cures

- Tough resin matrix giving good laminate mechanical properties

- DNV-GL & Lloyds Register Certified formats available

- Low Toxicity Hardener Formulations o Improved Hazard Labelling o CMR & SVHC** Free of Reduced Environmental Hazards

- Formulated with Gurit LRT (Light Reflective Technology) as standard

The viscosity of Ampreg™ 31 has been optimised for good fabric wet-out whilst maintaining good drainage resistance for application on vertical surfaces. Ampreg™ 31 has been designed to give excellent mechanical and thermal properties from both ambient temperature cures and moderate temperature postcures (50°C). This system is available with the full range of Ampreg™ 3X hardener speeds, from Fast to Extra Slow.

The unique formulation offers improved health & safety through the careful selection of low toxicity raw materials as well as Light Reflective Technology which in conjunction with a UV light-source can detect droplets as small as 1mm for easy identification of contamination to improve industrial hygiene.

Additional information

| Hardener | Fast, Slow |

|---|---|

| Size (Epoxy + Hardener kit) | 1.26 kg, 4.66 KG |