Description

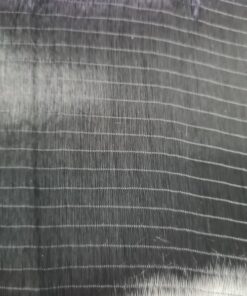

Enhanced Composites carbon cloth uses a 12k T700 carbon fibre yarn that is spread out thin like the standard spread tow fabrics. Our spread-tow is a carbon fibre fabric with 16 mm wide carbon tows placed in a plain weave pattern, creating the checkerboard appearance of plain weave carbon fibre but in a much larger pattern.

Reduced fibre crimp angle allows for a stronger composite part as well as minimizes excess resin consumption to provide the lightest, strongest part possible. Due to its lightweight nature, visual appearance and improved performance, compared to traditional textiles, our Spread Tow fabrics are ideally suited to high-performance applications such as sports and leisure equipment, automotive and aerospace.

- Attractive aesthetic finish: ideal for the production of both parts and tooling. No print-through issues on gelcoats.

- Improved mechanical performance as a reduced thickness compared to standard 2D fabrics using 1K fibres.

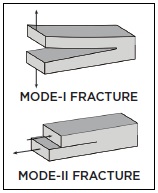

- High resistance to crack propagation for improved damage tolerance.

- Spread tow also has proven useful in the design of laminates that withstand significantly greater stress before first-ply failure and last-ply failure.

- Less crimp, so they can absorb more energy when suffering an impact. More crimp lowers the load-carrying maximum of the fabrics.

- Increased fibre volume fraction compared to 2D weaving. Weight savings.

- Improved coverage – reducing effects of multi-ply stacking.

- Compatible with with epoxy, phenolic, polyester and vinyl ester resins.