Prime 37 Infusion Epoxy Resin/Hardener 4.0 kg Pack

$360.80 incl. GST

- Same 100:29 resin to hardener mix ratio by weight across range of hardener speeds

- The lowest viscosity PRIMETM infusion resin & very low exotherm in thick sections

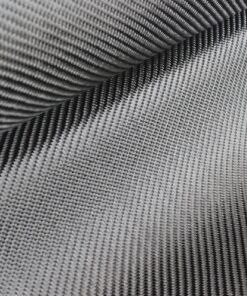

- Suitable for infusing structures that utilise carbon, aramid and glass fibres*

- Good mechanical properties

- DNV-GL and Lloyds Register Certifications in progress.

- Low Toxicity Ampreg™ 3X Hardener Formulations

- Improved Hazard Labelling

- CMR & SVHC Free**

- Reduced Environmental Hazards

2 in stock